|

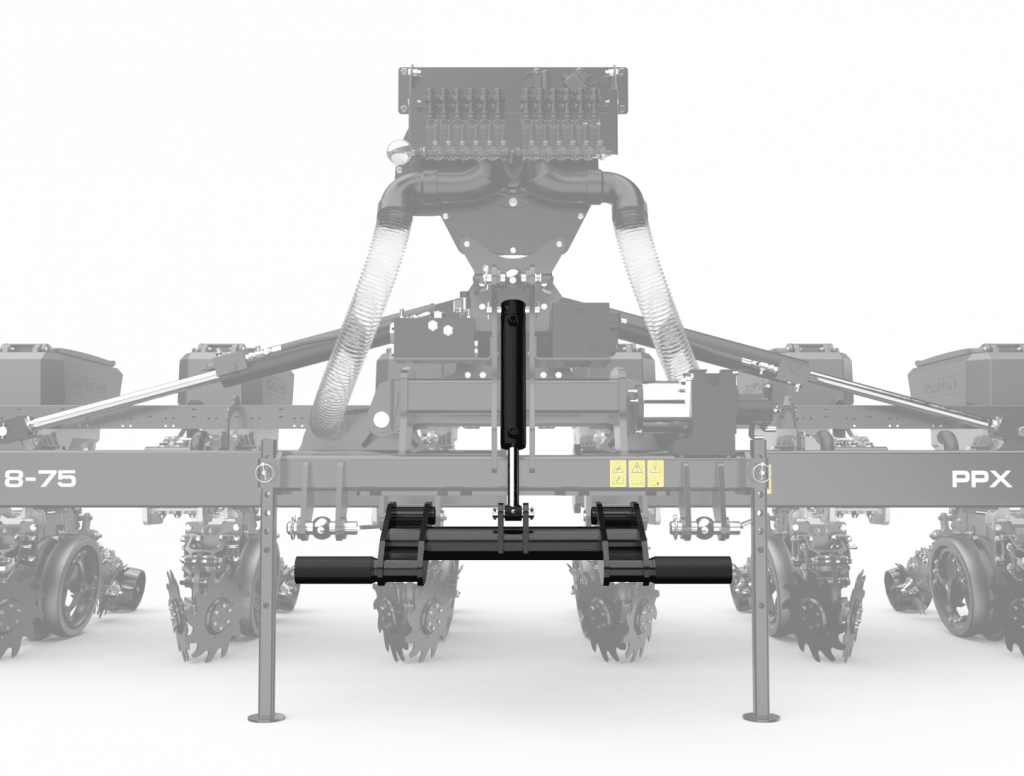

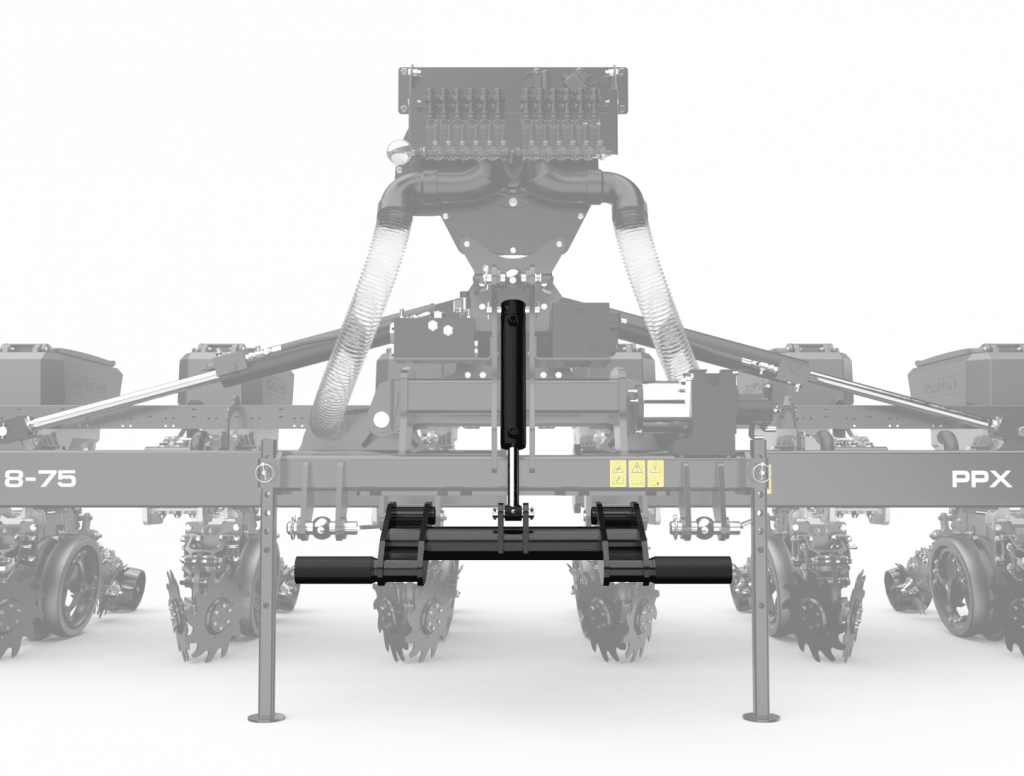

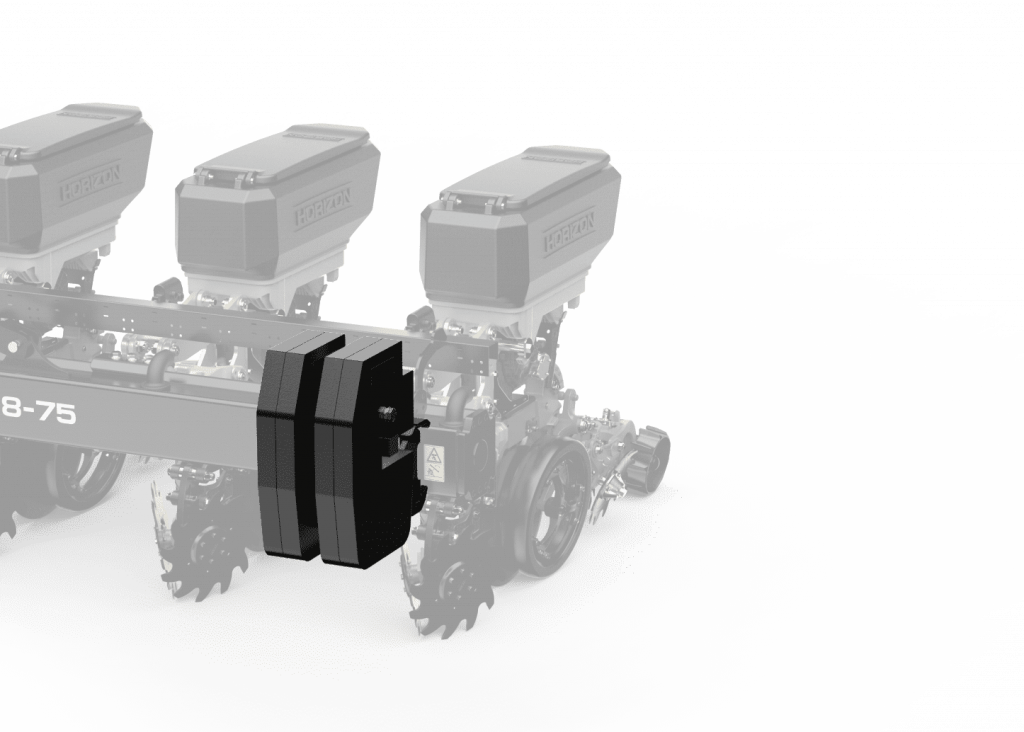

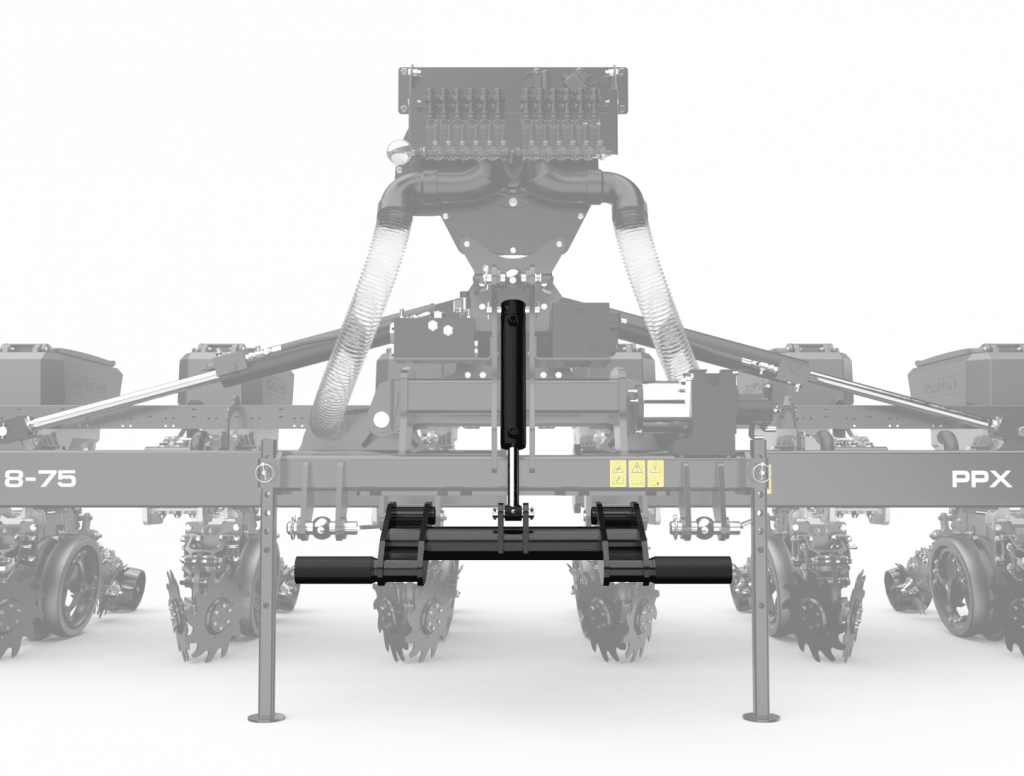

Weight Transfer Kit Dynamic weight control. When working in strip-till and no-till conditions the planter may require additional weight to ensure optimum ground engagement. The PPX Weight Transfer Kit allows the operator to transfer any weight between 0-800kg from the tractor linkage directly to the PPX row units and mitigates the need to carry bulky wing weights. |

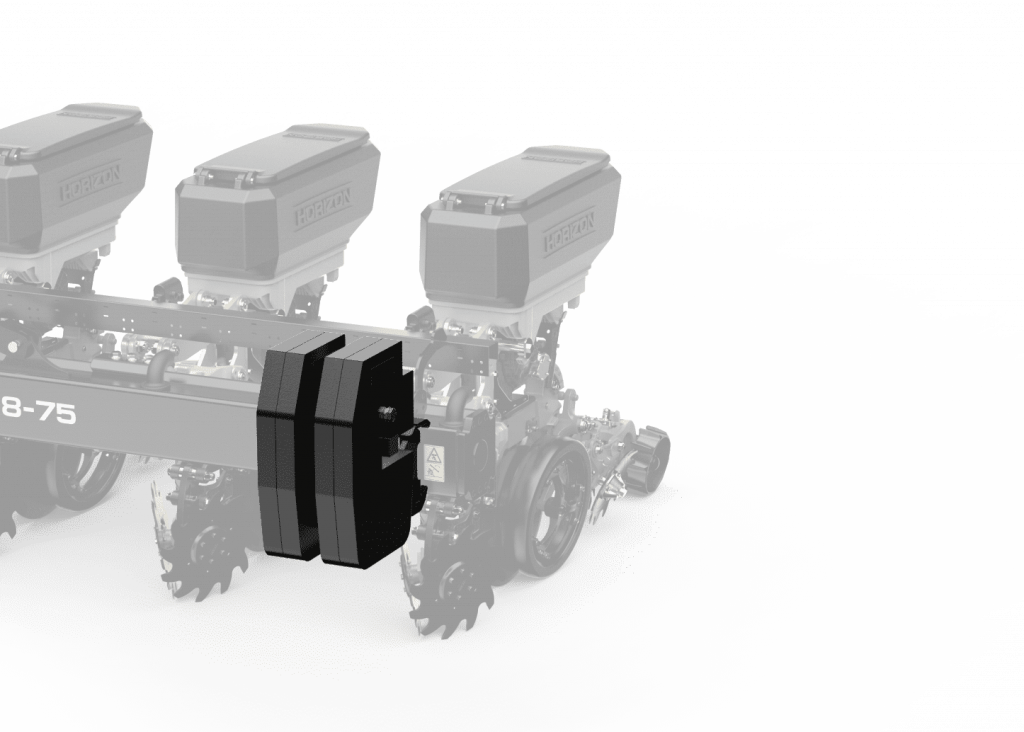

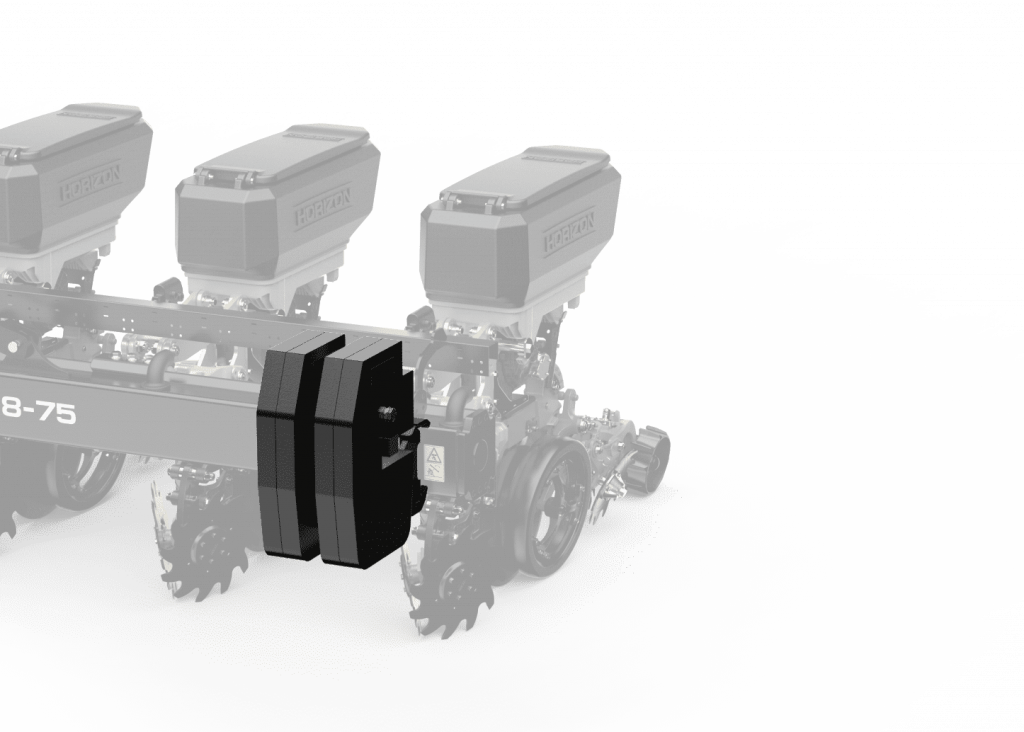

| Optional Wing Weights Wing weights can easily be added to the PPX thanks to the clamping toolbar profile. When planting into hard, no-till conditions, additional wing weights may be required to complement the 800kg of downforce already being applied by our Hydraulic Weight Transfer Kit. When both the Weight Transfer Kit and Wing Weights are working in conjunction they will enable the Automated Deltaforce system to achieve its maximum downforce capacity of 300kg if required. |

|

|

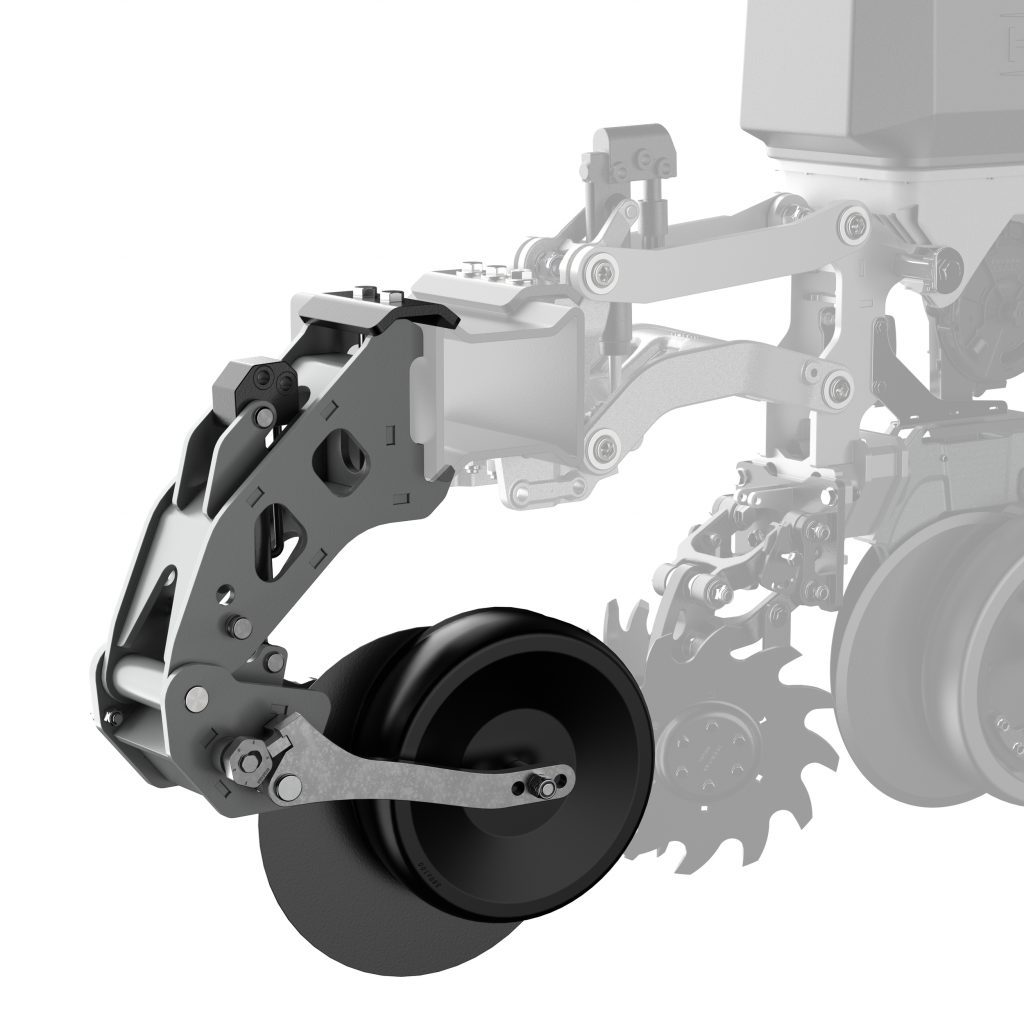

Optional Stabiliser Wheels The PPX can be configured with frame mounted stabiliser wheels to ensure consistent contour following on undulating fields. The wheels can be easily removed or adjusted, with a selection of positions for the wheel axle to accommodate for different tyre sizes. These wheels are designed to skim along the surface to minimise soil compaction. |

| Integrated Vacuum and Cable Management The PPX frame is now sealed and de-pressurised for cleaner cables and pipework. The PPX’s pneumatic vacuum is not housed inside the frame of the machine, eliminating cluttered pipework. The frame now features hose fittings which can be adjusted to accommodate for different row spacings. The PPX’s frame features a cable management tray, ensuring all wiring can be managed cleanly, properly and remain protected. |

|

|

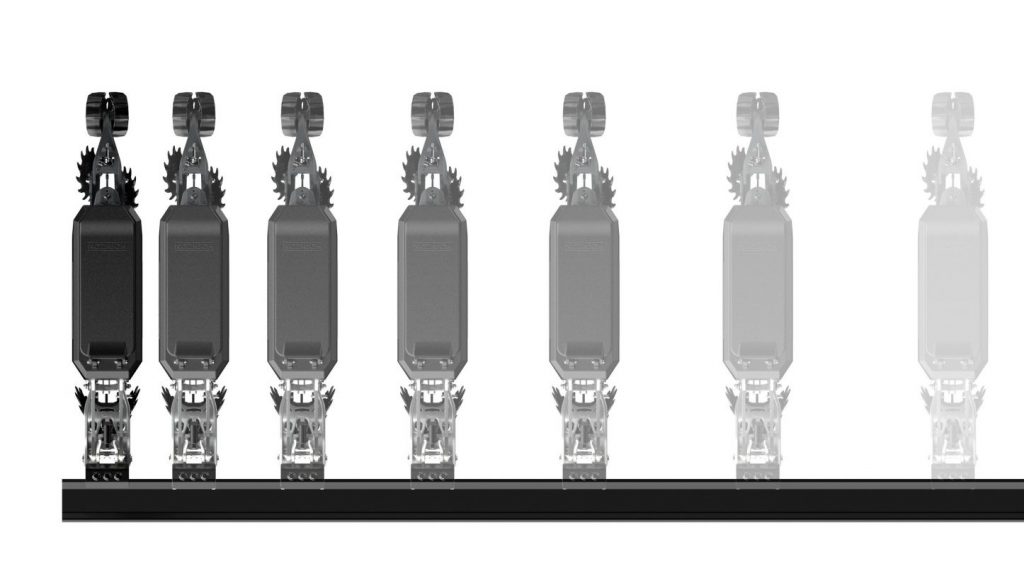

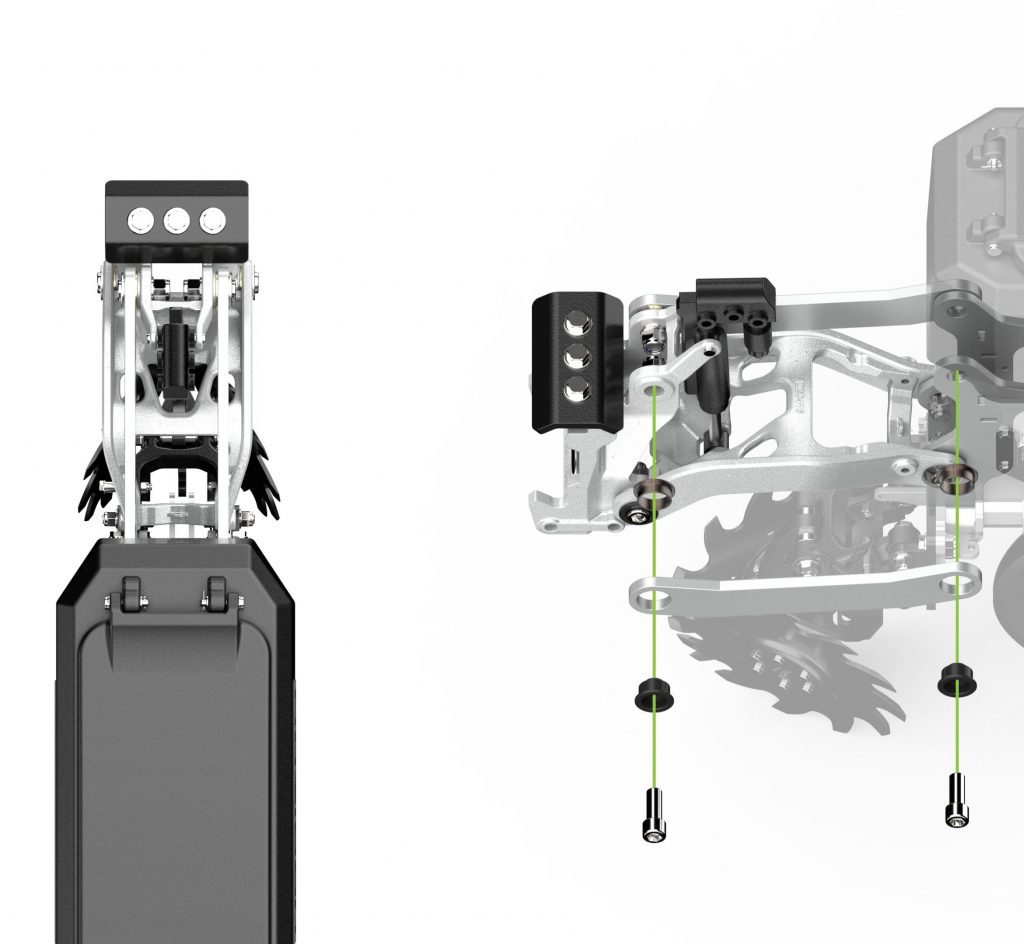

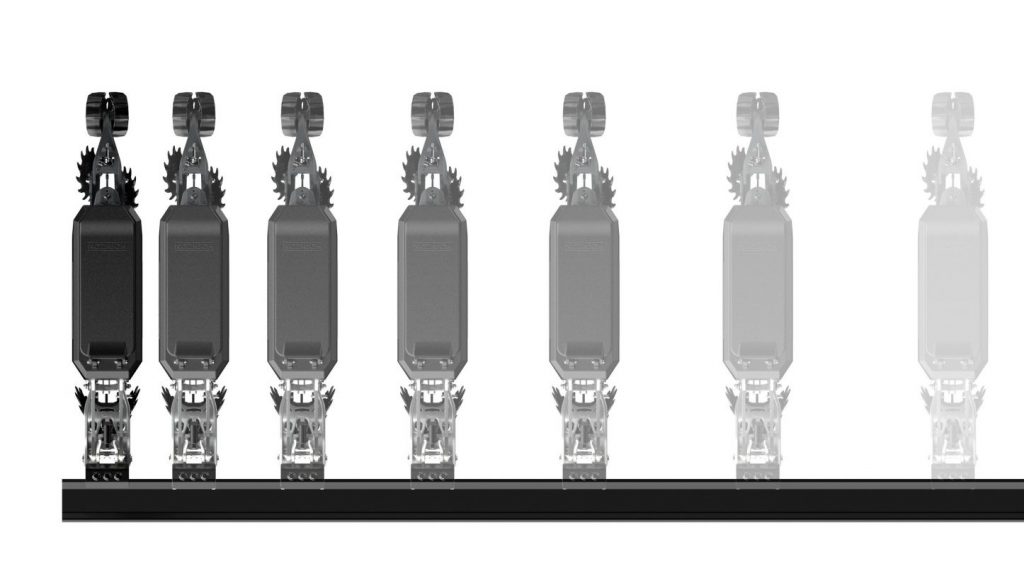

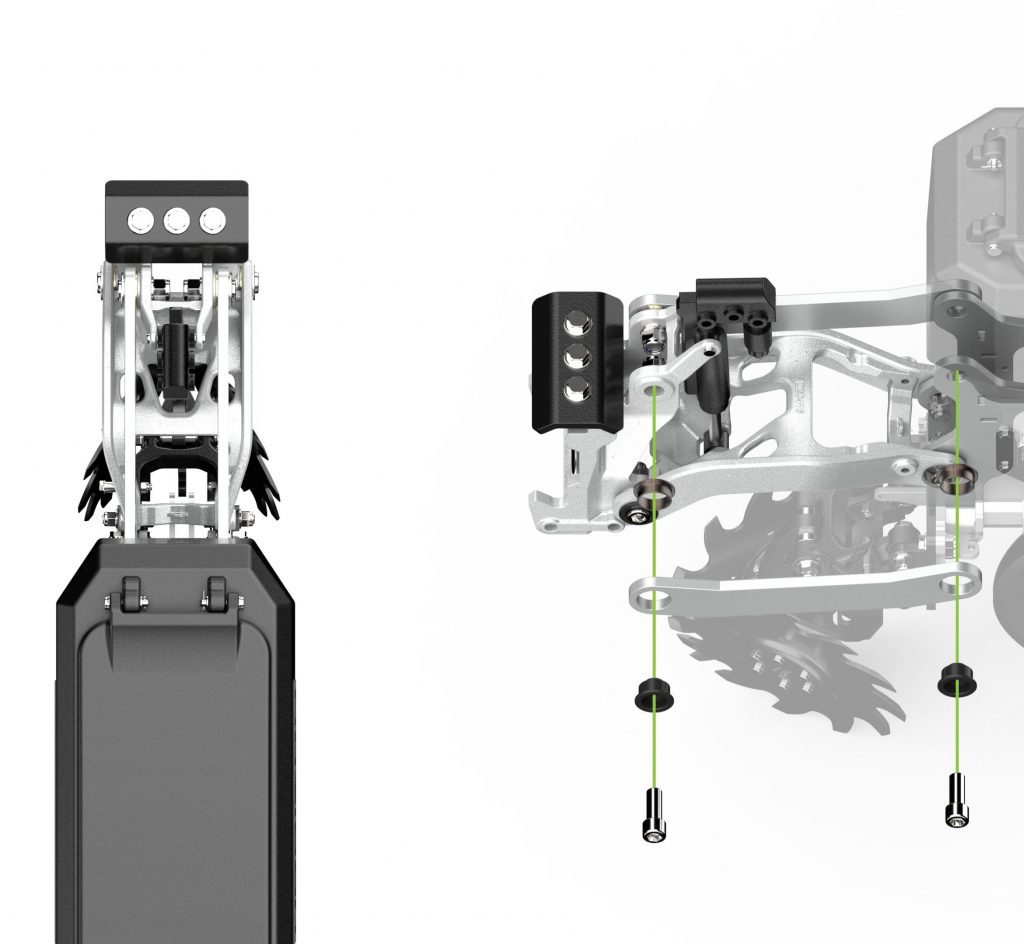

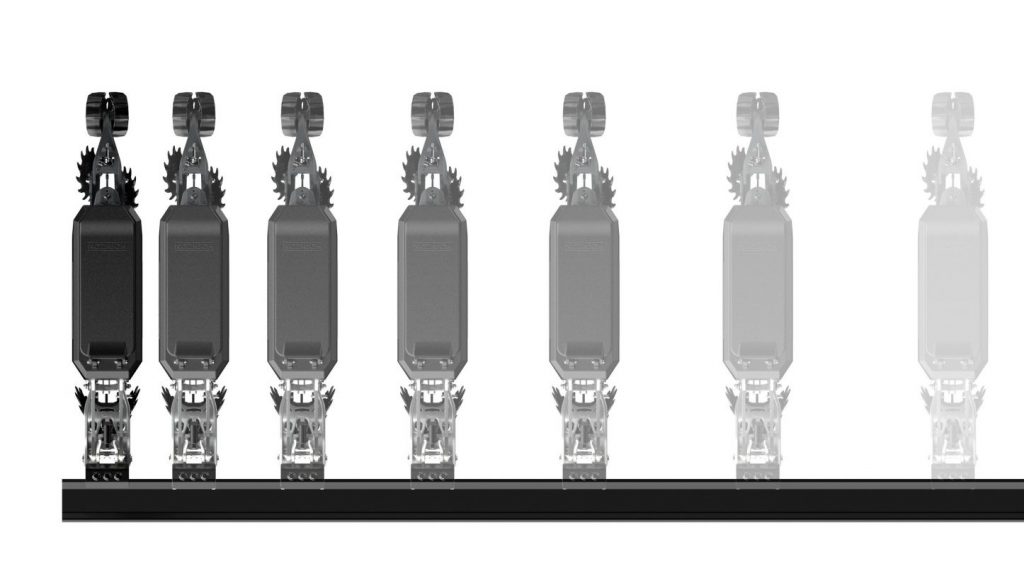

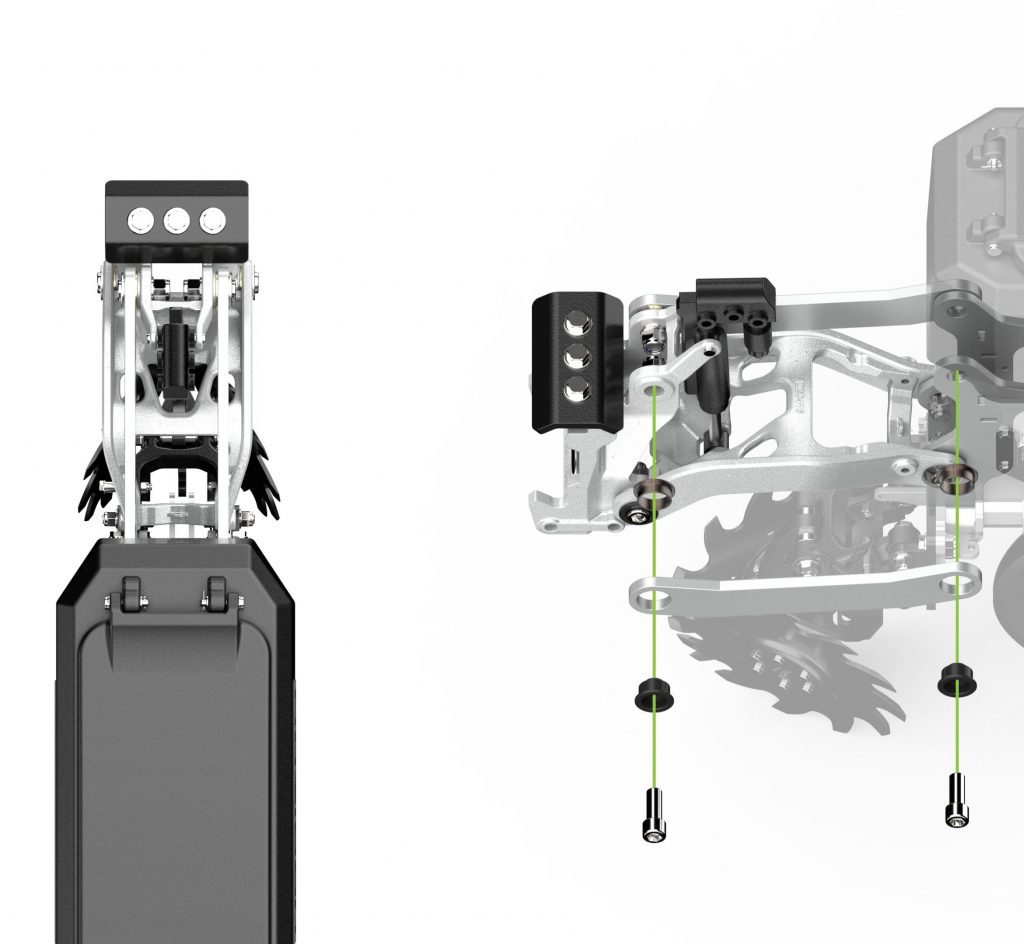

Flexible Row Spacings Configure your machine to any row spacing. The PPX row unit features a clamping system that allows virtually any row spacing to be configured by the farmer. Combined with our row units extremely narrow design, this means that we can support any spacing all the way down to 35cm. This clamping system also offers strength, durability and stiffness, meaning the row units will always track straight even in the hardest conditions. The row unit is held onto the toolbar with three M16 bolts, which can be loosed to either allow the row unit to slide, or to be removed completely. |

|

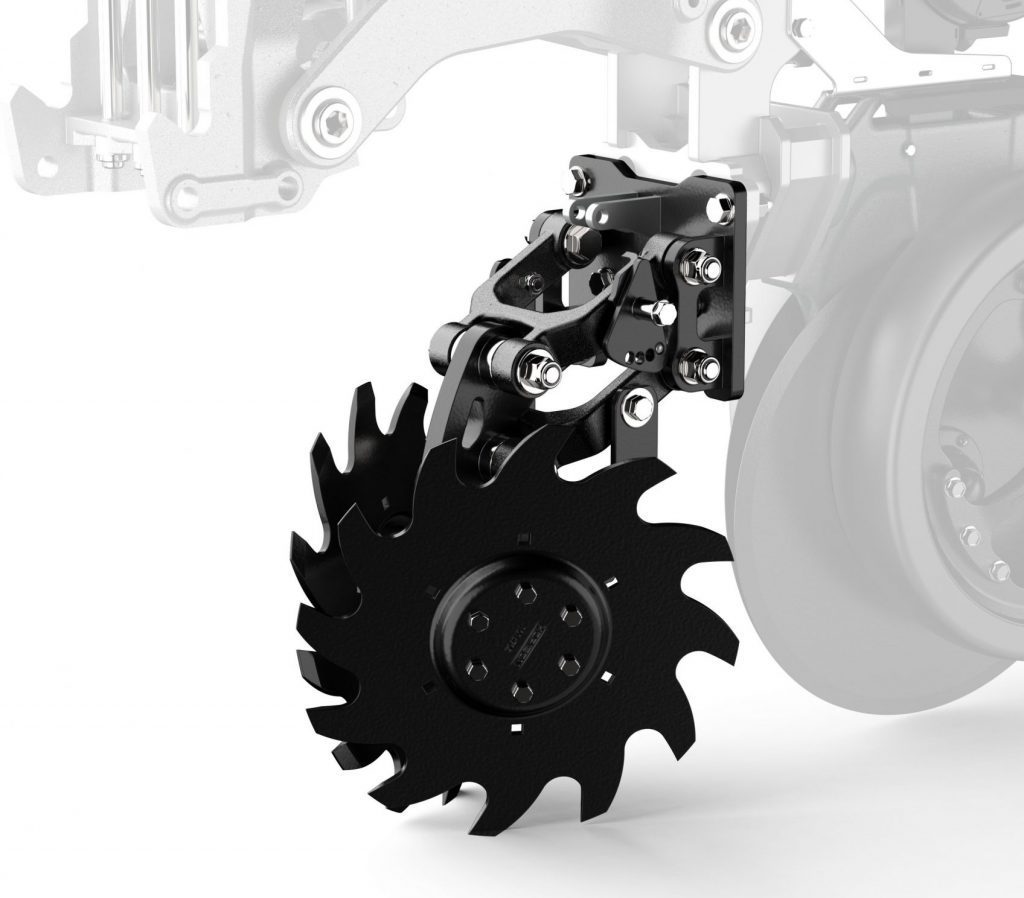

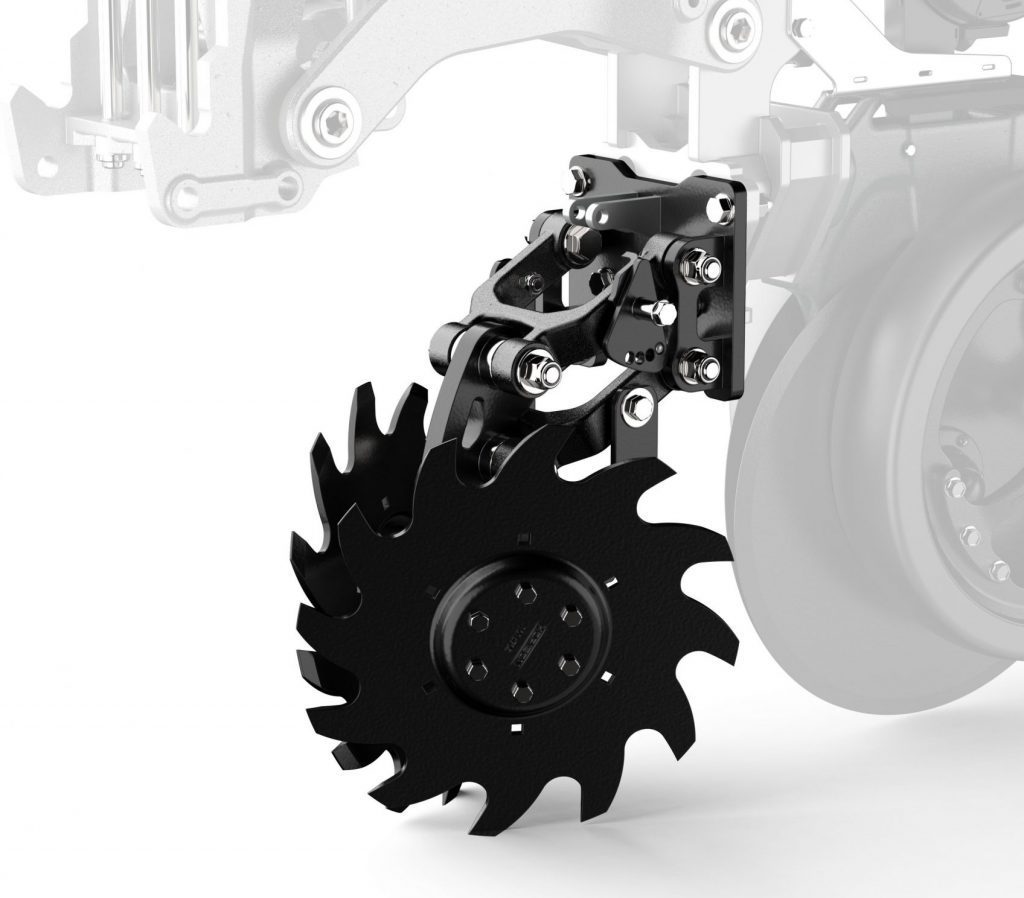

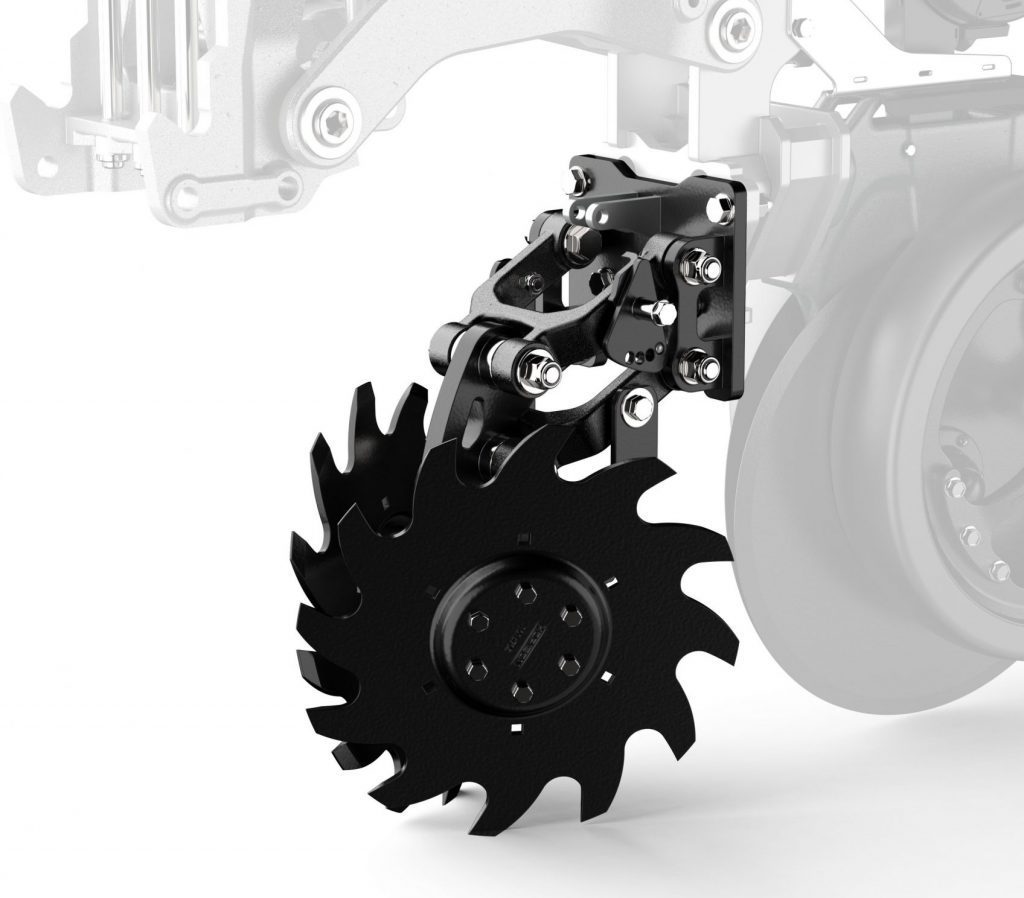

Row Cleaner |

|

|

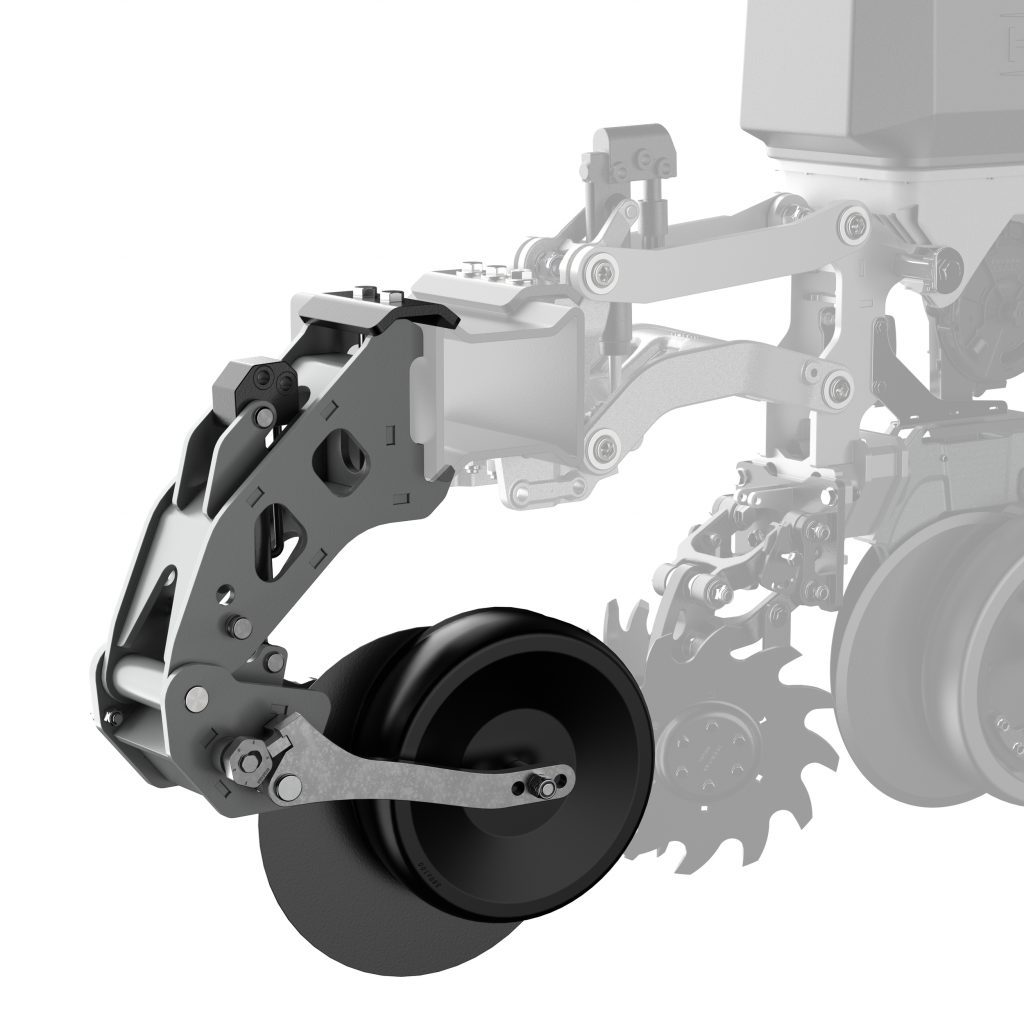

Standard Closing System |

|

Narrow, Reinforced Parallelogram |

|

| Nutrient delivery – Liquid. | Nutrient delivery – Granular. |

|

|

|

|

| Dribble Bar The dribble bar can be mounted on the closing system of the PPX row unit. The dribble bar applies nitrogen on the surface of the soil, where it can safely soak and travel towards the seed without any risk of seed burn. |

Seed Firmers Seed firmers such as the Keeton seed firmer can be used to apply phosphate or starter fertiliser directly into the slot with the seed. The seed firmer also ensures optimal seed-to-soil contact. |

Fertiliser Opener Our front fertiliser opener is ideal for delivering granular fertiliser directly into the soil. It achieves consistent off the row placement of fertiliser, ideal for nitrogen, and is mounted independently to the frame and can easily be adjusted. |

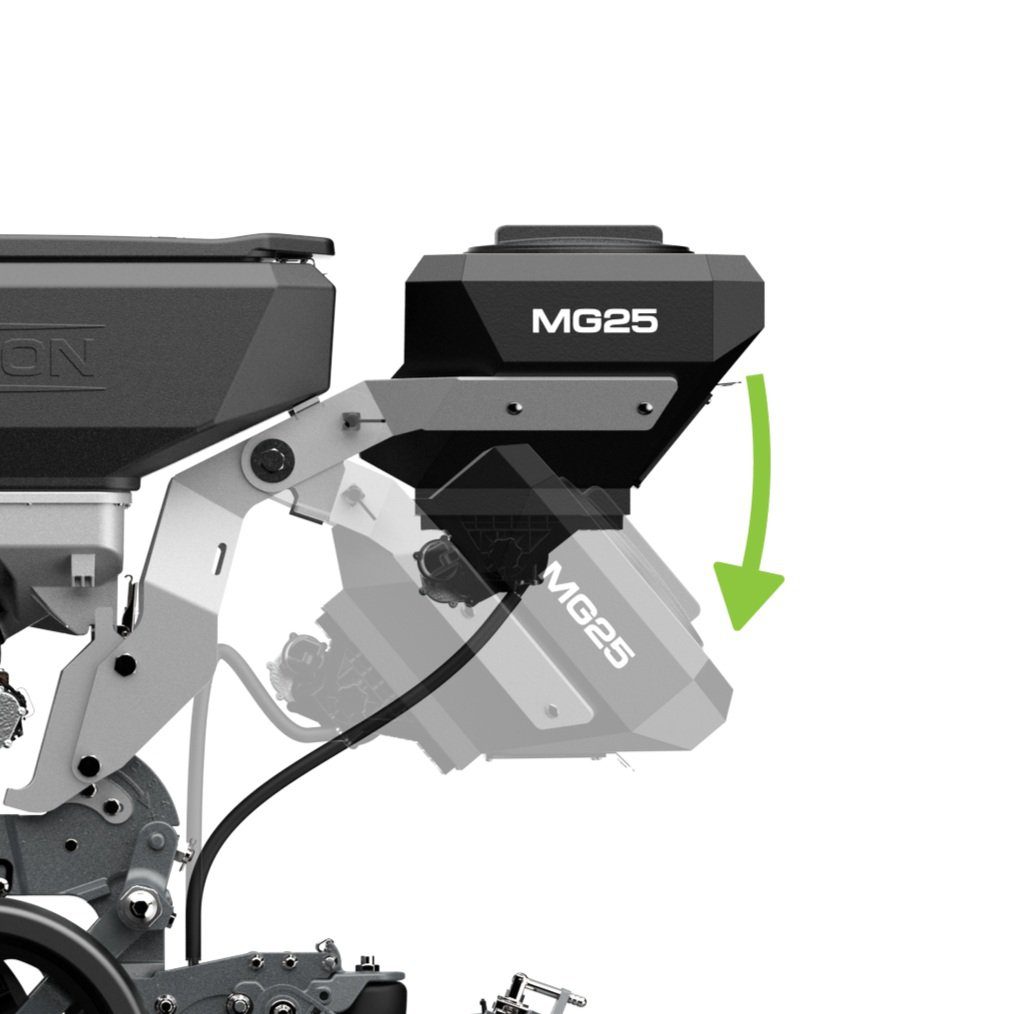

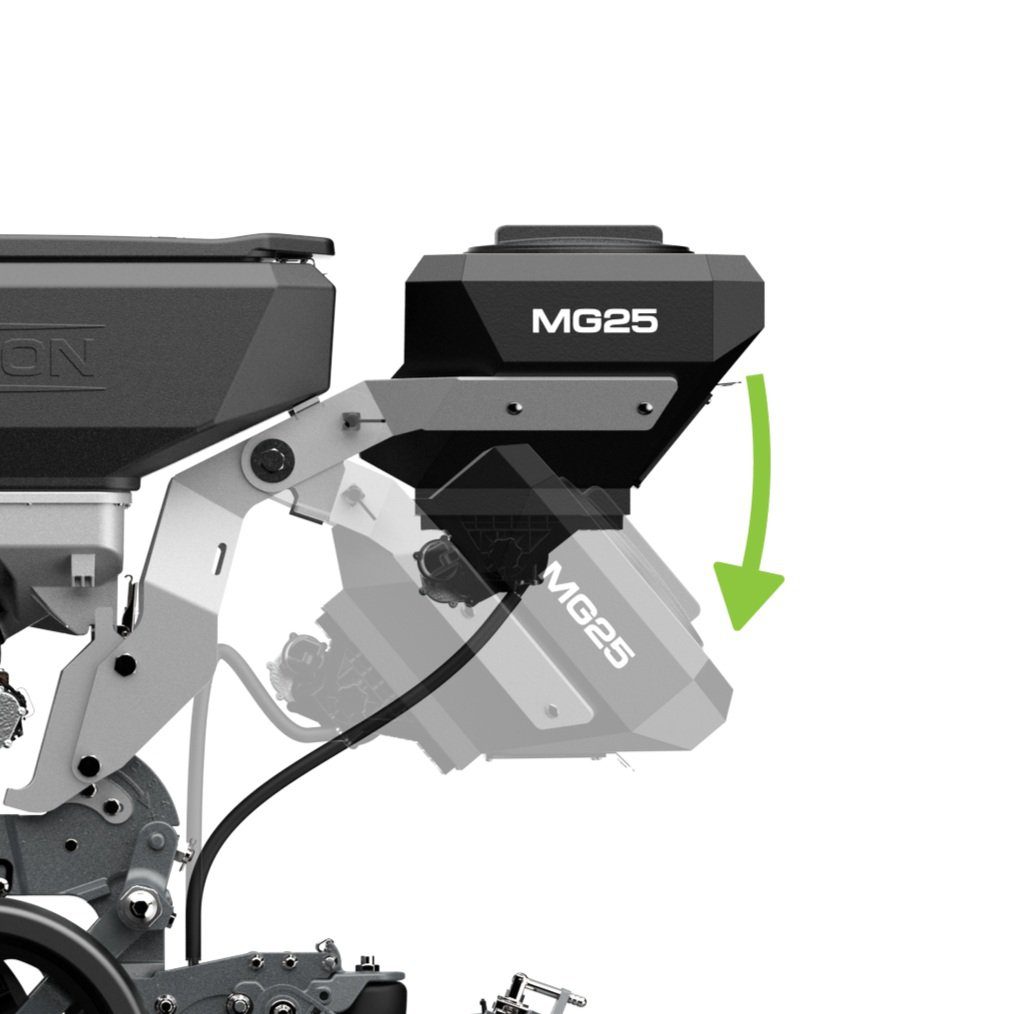

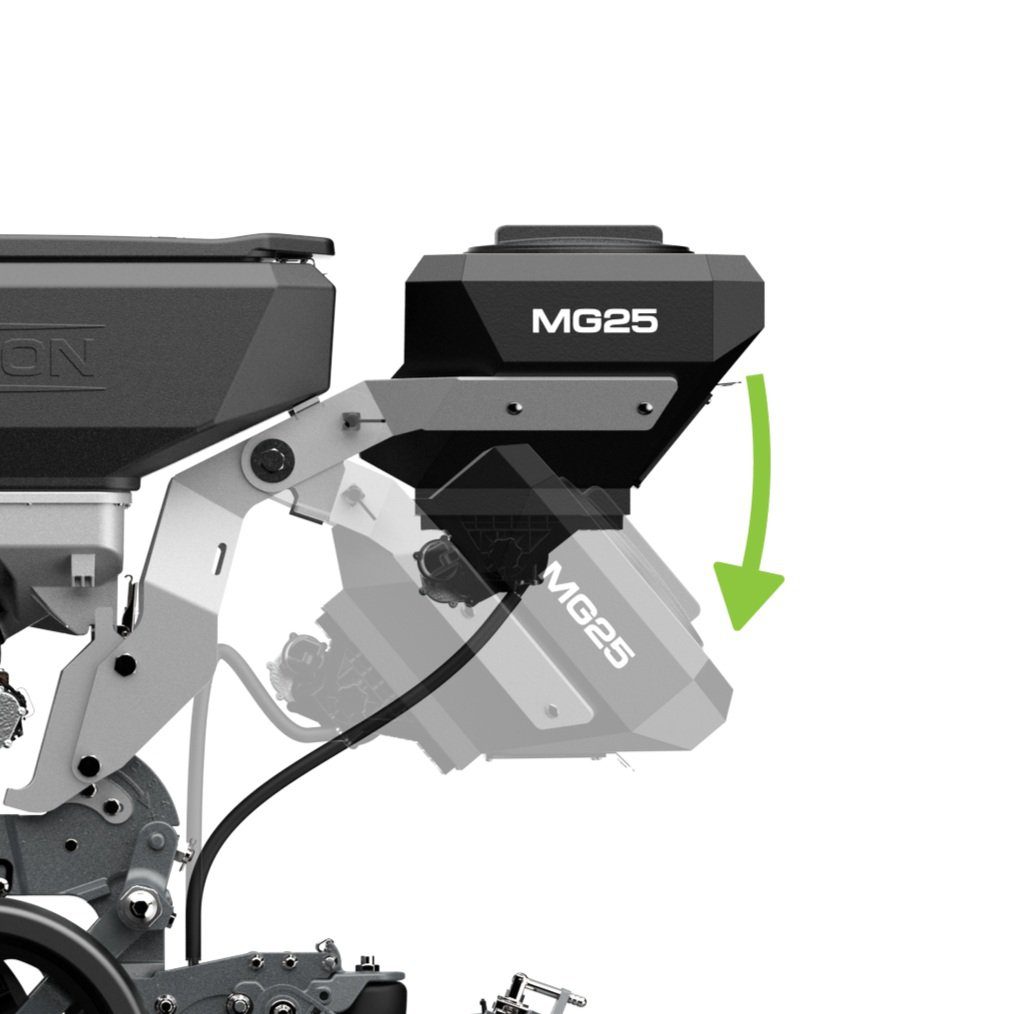

MG25 Delivery Tube The MG25 features a vDrive Insecticide metering system, which can dose insecticide directly into the furrow through a stainless steel tube. The hopper is not pressurised, and the insecticide is propelled only by gravity. |

Granular Hoppers

Hoppers and delivery methods to suit your needs.

|

|

|

FT2200 |

GH400 The GH400 is a compact, modular and highly configurable small hopper designed for a variety of applications and machines. Featuring the DSX metering system, the GH400 is pressurised and capable of distributing a variety of products. Designed for use with the PPX and SPX, the GH400-O is a standalone seeding hopper that features a turbine and integrated distribution box suitable for machines with 4-12 outlets. Learn more about the GH400 |

Row crop establishment is changing, with farmers now looking to reduce soil disturbance ahead of the planter operation. Therefore a new generation of planter is required to operate across a variety of field scenarios, such as fully cultivated, min-till, strip-till and no-till soils.

Powered by Precision Planting technology, the PPX Planter has been designed to perfectly place seed into the optimal growing environment, even in the most challenging environments.

High volumes of crop residue, hard no-till stubbles or uneven and lumpy strip till seedbeds are just some of the challenges the PPX can comfortably handle. The PPX won’t only perform in these challenging scenarios, it will also capture live data and make automated adjustments to ensure the optimal growing environment is achieved for every seed.

|

Weight Transfer Kit Dynamic weight control. When working in strip-till and no-till conditions the planter may require additional weight to ensure optimum ground engagement. The PPX Weight Transfer Kit allows the operator to transfer any weight between 0-800kg from the tractor linkage directly to the PPX row units and mitigates the need to carry bulky wing weights. |

| Optional Wing Weights Wing weights can easily be added to the PPX thanks to the clamping toolbar profile. When planting into hard, no-till conditions, additional wing weights may be required to complement the 800kg of downforce already being applied by our Hydraulic Weight Transfer Kit. When both the Weight Transfer Kit and Wing Weights are working in conjunction they will enable the Automated Deltaforce system to achieve its maximum downforce capacity of 300kg if required. |

|

|

Optional Stabiliser Wheels The PPX can be configured with frame mounted stabiliser wheels to ensure consistent contour following on undulating fields. The wheels can be easily removed or adjusted, with a selection of positions for the wheel axle to accommodate for different tyre sizes. These wheels are designed to skim along the surface to minimise soil compaction. |

| Integrated Vacuum and Cable Management The PPX frame is now sealed and de-pressurised for cleaner cables and pipework. The PPX’s pneumatic vacuum is not housed inside the frame of the machine, eliminating cluttered pipework. The frame now features hose fittings which can be adjusted to accommodate for different row spacings. The PPX’s frame features a cable management tray, ensuring all wiring can be managed cleanly, properly and remain protected. |

|

|

Flexible Row Spacings Configure your machine to any row spacing. The PPX row unit features a clamping system that allows virtually any row spacing to be configured by the farmer. Combined with our row units extremely narrow design, this means that we can support any spacing all the way down to 35cm. This clamping system also offers strength, durability and stiffness, meaning the row units will always track straight even in the hardest conditions. The row unit is held onto the toolbar with three M16 bolts, which can be loosed to either allow the row unit to slide, or to be removed completely. |

|

Row Cleaner |

|

|

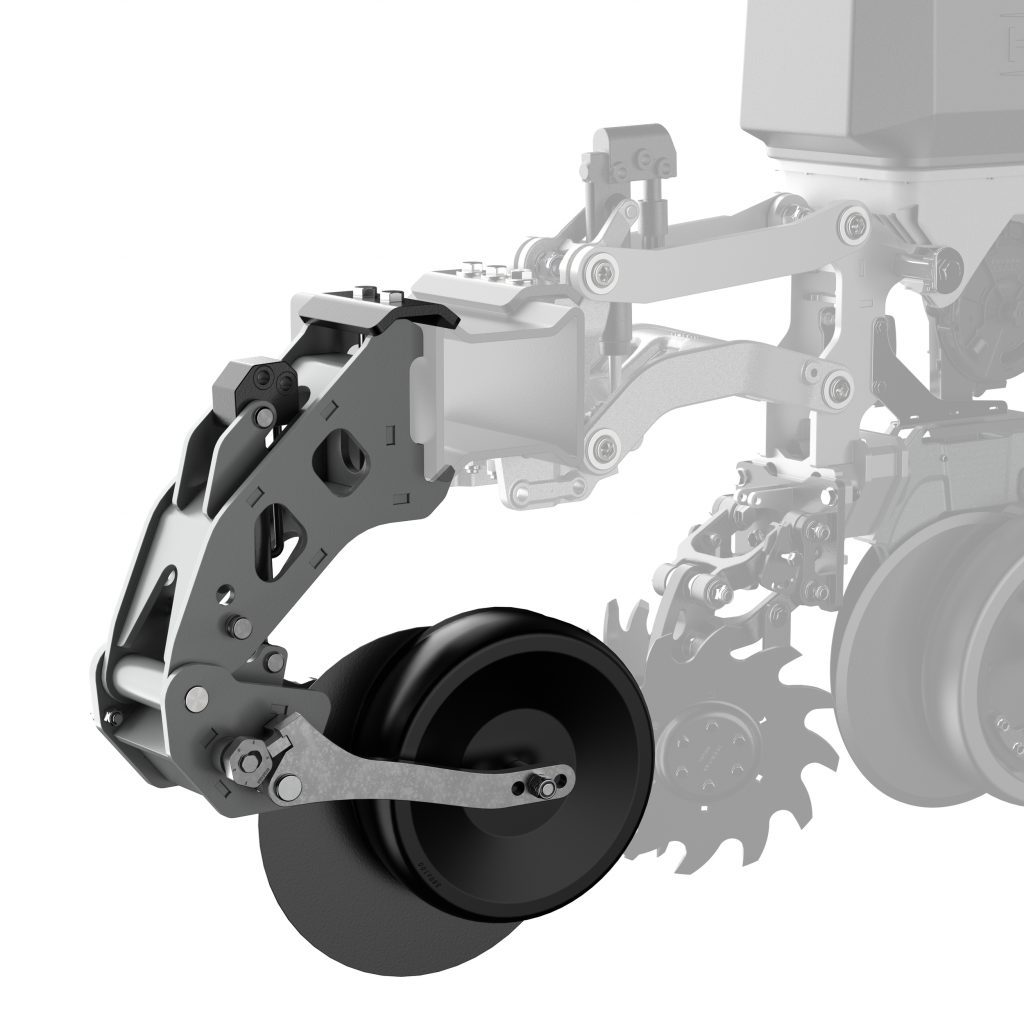

Standard Closing System |

|

Narrow, Reinforced Parallelogram |

|

| Nutrient delivery – Liquid. | Nutrient delivery – Granular. |

|

|

|

|

| Dribble Bar The dribble bar can be mounted on the closing system of the PPX row unit. The dribble bar applies nitrogen on the surface of the soil, where it can safely soak and travel towards the seed without any risk of seed burn. |

Seed Firmers Seed firmers such as the Keeton seed firmer can be used to apply phosphate or starter fertiliser directly into the slot with the seed. The seed firmer also ensures optimal seed-to-soil contact. |

Fertiliser Opener Our front fertiliser opener is ideal for delivering granular fertiliser directly into the soil. It achieves consistent off the row placement of fertiliser, ideal for nitrogen, and is mounted independently to the frame and can easily be adjusted. |

MG25 Delivery Tube The MG25 features a vDrive Insecticide metering system, which can dose insecticide directly into the furrow through a stainless steel tube. The hopper is not pressurised, and the insecticide is propelled only by gravity. |

Granular Hoppers

Hoppers and delivery methods to suit your needs.

|

|

|

FT2200 |

GH400 The GH400 is a compact, modular and highly configurable small hopper designed for a variety of applications and machines. Featuring the DSX metering system, the GH400 is pressurised and capable of distributing a variety of products. Designed for use with the PPX and SPX, the GH400-O is a standalone seeding hopper that features a turbine and integrated distribution box suitable for machines with 4-12 outlets. Learn more about the GH400 |

|

Weight Transfer Kit Dynamic weight control. When working in strip-till and no-till conditions the planter may require additional weight to ensure optimum ground engagement. The PPX Weight Transfer Kit allows the operator to transfer any weight between 0-800kg from the tractor linkage directly to the PPX row units and mitigates the need to carry bulky wing weights. |

| Optional Wing Weights Wing weights can easily be added to the PPX thanks to the clamping toolbar profile. When planting into hard, no-till conditions, additional wing weights may be required to complement the 800kg of downforce already being applied by our Hydraulic Weight Transfer Kit. When both the Weight Transfer Kit and Wing Weights are working in conjunction they will enable the Automated Deltaforce system to achieve its maximum downforce capacity of 300kg if required. |

|

|

Optional Stabiliser Wheels The PPX can be configured with frame mounted stabiliser wheels to ensure consistent contour following on undulating fields. The wheels can be easily removed or adjusted, with a selection of positions for the wheel axle to accommodate for different tyre sizes. These wheels are designed to skim along the surface to minimise soil compaction. |

| Integrated Vacuum and Cable Management The PPX frame is now sealed and de-pressurised for cleaner cables and pipework. The PPX’s pneumatic vacuum is not housed inside the frame of the machine, eliminating cluttered pipework. The frame now features hose fittings which can be adjusted to accommodate for different row spacings. The PPX’s frame features a cable management tray, ensuring all wiring can be managed cleanly, properly and remain protected. |

|

|

Flexible Row Spacings Configure your machine to any row spacing. The PPX row unit features a clamping system that allows virtually any row spacing to be configured by the farmer. Combined with our row units extremely narrow design, this means that we can support any spacing all the way down to 35cm. This clamping system also offers strength, durability and stiffness, meaning the row units will always track straight even in the hardest conditions. The row unit is held onto the toolbar with three M16 bolts, which can be loosed to either allow the row unit to slide, or to be removed completely. |

|

Row Cleaner |

|

|

Standard Closing System |

|

Narrow, Reinforced Parallelogram |

|

| Nutrient delivery – Liquid. | Nutrient delivery – Granular. |

|

|

|

|

| Dribble Bar The dribble bar can be mounted on the closing system of the PPX row unit. The dribble bar applies nitrogen on the surface of the soil, where it can safely soak and travel towards the seed without any risk of seed burn. |

Seed Firmers Seed firmers such as the Keeton seed firmer can be used to apply phosphate or starter fertiliser directly into the slot with the seed. The seed firmer also ensures optimal seed-to-soil contact. |

Fertiliser Opener Our front fertiliser opener is ideal for delivering granular fertiliser directly into the soil. It achieves consistent off the row placement of fertiliser, ideal for nitrogen, and is mounted independently to the frame and can easily be adjusted. |

MG25 Delivery Tube The MG25 features a vDrive Insecticide metering system, which can dose insecticide directly into the furrow through a stainless steel tube. The hopper is not pressurised, and the insecticide is propelled only by gravity. |

Granular Hoppers

Hoppers and delivery methods to suit your needs.

|

|

|

FT2200 |

GH400 The GH400 is a compact, modular and highly configurable small hopper designed for a variety of applications and machines. Featuring the DSX metering system, the GH400 is pressurised and capable of distributing a variety of products. Designed for use with the PPX and SPX, the GH400-O is a standalone seeding hopper that features a turbine and integrated distribution box suitable for machines with 4-12 outlets. Learn more about the GH400 |